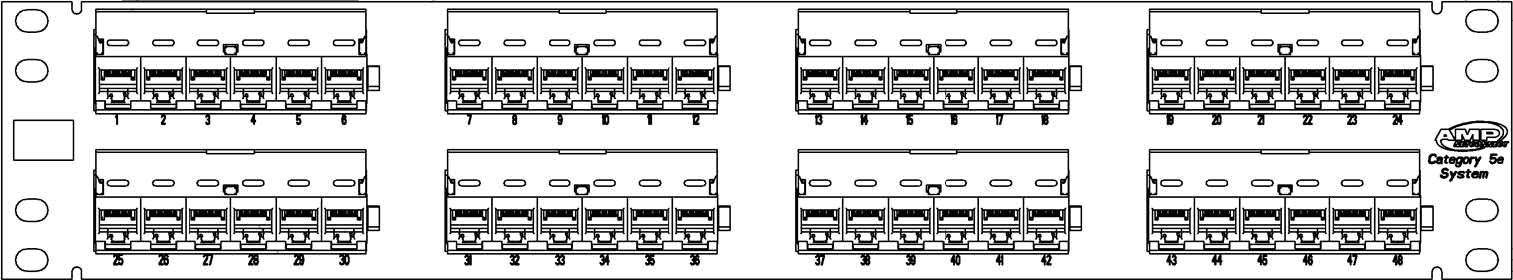

SL Series 110Connect Category 5E Patch Panel

Description

AMP NETCONNECT Category 5E SL Series 110Connect Patch Panels exceed TIA/EIA-568-B.2, TIA/EIA 568-C and ISO/IEC 11801 requirements for Category 5E/Class D component performance, EIA-364, IEC 60068, IEC 60512 and ASTM D4566-98. The AMP NETCONNECT Category 5E System complies with all of the performance requirements for current and proposed applications such as Gigabit Ethernet, (1000BASE-T), 10 and 100BASE-Tx, token ring, 155 Mbps ATM, 100 Mbps TP-PMD, ISDN, analog (Broadband, Baseband) and digital video and analog and digital (VoIP) voice. The universal wiring label permits field installation to both T568A or T568B wiring while simplifying ordering and inventory. The "6-pack" modules accept 9mm and 12mm labels (included) as well as color-coded icons. The jacks may be individually replaced if necessary.

Specification (text in brackets [] requires a choice) Category 5E patch panels shall be [insert height] high and provide [insert number of ports] modular jack ports, wired to [T568A or T568B] . Patch panels shall be configured as 6-port modules with individually replaceable jacks. The front of each module shall be capable of accepting 9mm to 12mm labels. Each port shall be capable of accepting an icon to indicate its function. Patch panels shall terminate the building cabling on 110-style insulation displacement connectors (IDC). The installed system shall comply with the Category 5E performance characteristics listed in the following table [insert table from back page] . Patch panels must be UL Listed under file number E81956. Patch panels shall be AMP NETCONNECT part number [1479153-X, 1479154-X, 1479155-X, 1479156-X] or an approved equivalent.

[include Performance Characteristics table from page 2]

Modular Jacks shall be compatible with AMP NETCONNECT SL Series Termination Tool part number 1725150-1. Each modular jack shall be provided with a bend-limiting strain relief. The strain relief shall provide cylindrical support to limit the bend radius at the point of termination. [Each jack shall incorporate an integral, hinged dust cover] . Modular jacks shall be UL Listed under file number E81956. Modular jacks shall be AMP NETCONNECT part number [1375191-X, 1375190-X, 1375189-1 or 1479717-1 (X denotes color, see part number table) ] and be [almond, black, white, gray, orange, blue, red, yellow, green, violet, or electrical ivory] in color.

Part Numbers

Description | Number of Ports | Height, in. | Width, in. | Part Number | | 12 | 10.015* | 2.328 | 1479153-2 | Category 5E SL Series 110Connect Patch Panel | 24 48 | 1.75 3.5 | 19 | 1479154-2 1479155-2 | | 96 | 7 | | 1479156-2 |

|

1479153-X, 1479154-X, 1479155-X, 1479156-X

Worst-Case

Frequency, MHz | Insertion Loss, dB | Return Loss, dB | NEXT, dB | FEXT, dB |

| Spec | AMP | Spec | AMP | Spec | AMP | Spec | AMP |

1 | 0.1 | 0.01 | 30 | 58.3 | 65.0 | 87.3 | 65.0 | 86.6 |

4 | 0.1 | 0.02 | 30 | 48.8 | 65.0 | 76.6 | 63.1 | 76.1 |

8 | 0.1 | 0.03 | 30 | 43.7 | 64.9 | 70.7 | 57.0 | 70.5 |

10 | 0.1 | 0.02 | 30 | 42.2 | 63.0 | 69.1 | 55.1 | 68.9 |

16 | 0.2 | 0.1 | 30 | 38.5 | 58.9 | 64.8 | 51.0 | 65.3 |

20 | 0.2 | 0.08 | 30 | 36.7 | 57.0 | 63.0 | 49.1 | 63.5 |

25 | 0.2 | 0.06 | 30 | 35.0 | 55.0 | 61.1 | 47.1 | 61.7 |

31.25 | 0.2 | 0.04 | 30 | 33.1 | 53.1 | 58.9 | 45.2 | 60.0 |

62.5 | 0.3 | 0.06 | 24 | 27.5 | 47.1 | 52.6 | 39.2 | 54.7 |

100 | 0.4 | 0.08 | 20 | 24.0 | 43.0 | 47.6 | 35.1 | 51.0 |

155 | - | 0.2 | - | 20.2 | - | 40.2 | - | 41.3 |

200 | - | 0.3 | - | 18.0 | - | 37.4 | - | 39.1 |

250 | - | 0.4 | - | 16.0 | - | 35.0 | - | 37.1 |

300 | - | 0.3 | - | 14.5 | - | 33.5 | - | 35.6 |

350 | - | 0.3 | - | 13.1 | - | 32.1 | - | 34.2 |

Modular Jack Housing – | Polyphenylene oxide, 94V-0 rated |

110 Connecting Blocks – | Polycarbonate, 94V-0 rated |

| Beryllium copper, plated with 1.27µm [50µin] thick gold in localized area and 3.81µm |

Contacts – | [150µin] minimum |

| thick nickel under plate |

Insulation Displacement Contacts – | Phosphorous bronze, plated with 3.81µm [150µin] minimum thick bright tin-lead over 1.27µm [50µin] minimum thick nickel under plate |

Integral Dust Cover – | Polycarbonate |

Shield – | Copper zinc alloy 260, pre-plated with bright nickel |

Strain Relief – | Polycarbonate |

Panel – | black powder-coated steel |

Connector Housing Interface – | Polyester Molding Compound, Black |

Electrical Characteristics | |

Modular Jack – | 750 mating cycles |

110 Contacts – | 200 terminations |

Pull Force – | 20lbs (89N) |

Voltage – | 150VAC max |

Operating Temperature – | -40°to 70°C (-40°– 158°F) |

Contact resistance – | 20 milliohms maximum |

Insulation Resistance – | 500 Meg ohms minimum |

Voltage proof – | 1000VAC, IEC 60512-4-1 |

Vibration Test – | IEC 60512-6-4 |

Approvals | |

UL File Number E81956, CSA | |

RoHS Compliant | |

FCC PART 68 SUBPART F | |